Accoya

Accoya® is acetylated pine timber. Durable, non-toxic, insect barrier and dimensionally stable with 25 year warranty.

What is acetylated timber?

The process behind Acetylation.

The process behind Acetylation.By altering the modular structure of wood to resist water absorption, we ensure water and warping resistance. Our wood comes with a 50-year durability warranty, and boasts accreditations and certifications such as Cradle to Cradle, SGBC, LEED, termite-resistance, and Class 3 fire rating certifications

ACCOYA® WOOD KEY FEATURES

A sustainably consistent supply of durable, non-toxic, and dimensionally stable wood makes it an ideal material for manufacturing high performance exterior timber products such as wood siding, outside decking, cladding, landscape timbers and joinery.

Barefoot friendly

Barefoot friendly Consistant quality throughout

Consistant quality throughout Dimensionally stable

Dimensionally stable Excellent machinability

Excellent machinability From sustainable sources

From sustainable sources Insect barrier

Insect barrier Naturally Beautiful wood

Naturally Beautiful wood Naturally insulating

Naturally insulating Non-toxic and recyclable

Non-toxic and recyclable Outstanding durability

Outstanding durability Perfect for Coating

Perfect for Coating Retained strength and hardness

Retained strength and hardness

NATURALLY INSULATING

- Offers improved insulation in comparison with commonly used hardwood and softwood species

- Ideal for applications where energy conservation is important

RETAINED STRENGTH & HARDNESS

- The process does not compromise the wood’s strength

- Hardness is increased

- High strength to weight ratio makes it suitable for challenging applications

BAREFOOT FRIENDLY

- Ideal for all decking situations in extreme temperatures

- Low thermal gain

- Splinters are much less than other wood species when used for decking

EXCELLENT MACHINABILITY

- Easy to machine and process

- No special tools are required

INSECT BARRIER

- Indigestible to a wide range of insects, including termites

- Greatly reduced vulnerability

SUSTAINABLE SOURCE

- From FSC® and other regionally certified woods

- Naturally renewable

ACCOYA® Colour swatches

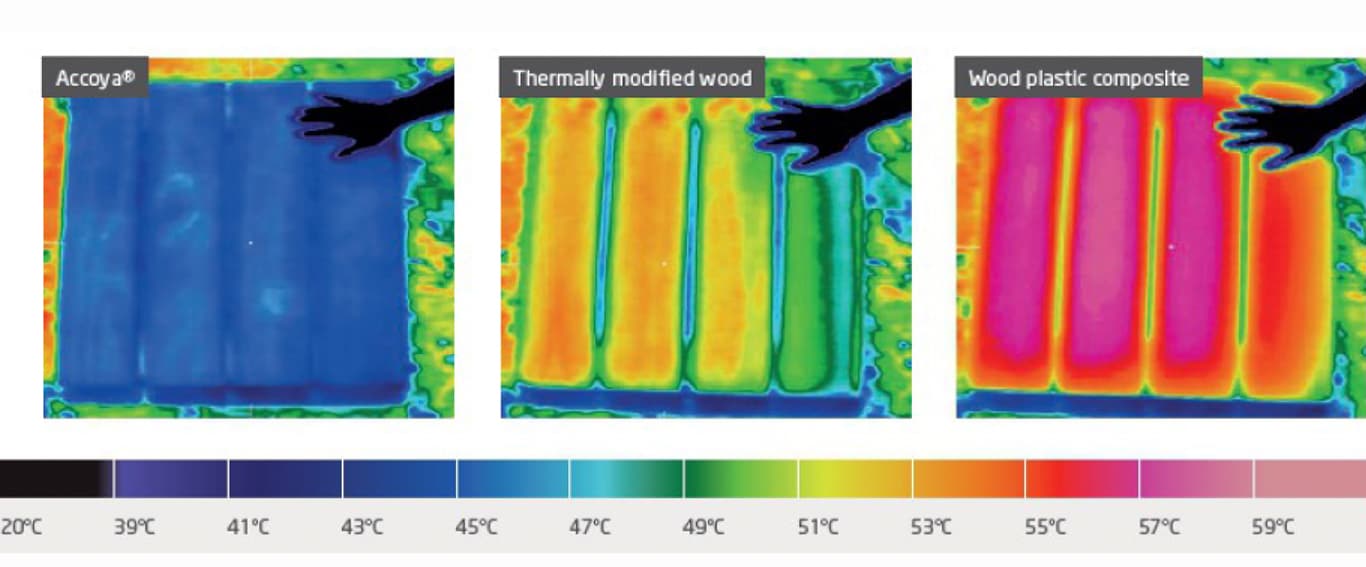

Thermal Gain on Decks

Decking and terrace under the sun is prone to thermal gain, and during the hot summer days, the deck temperature can reach over 65 °C.

Using a thermogram image analysis, Accoya®, was tested long side with three variants of WPC decking.

The ambient temperature of the test site was 32°C.

Accoya®39 ~ 47°C

Thermally modified wood47 ~ 51°C

Wood Plastic Composite53 ~ 57°C

The thermograms indicates Accoya®’s thermal gain is substantially less than the alternatives tested. This makes it truly “barefoot friendly” and resistance to cupping and splintering with prolonged weathering.

Installation

technical data

Standard Lengths

2.4m, 3.0m, 3.6m, 4.2m, 4.8m Please contact us for stock availability and delivery time.

- All dimensions are actual rough sawn.

- Accoya® wood is available in many other standard decking sizes and siding patterns from our partners.

A1: 4 sides primarily clear

A2: 3 sides primarily clear

FJ: Finger Jointed

Other grades and dimensions can be made. Please contact us for more information.

standard dimensions & Grades

INSECT DECAY

Accoya® wood is indigestible to a wide range of pests and an effective barrier to attack. For instance, when tested for termites according to AWPA E1 standards, appearance ratings consistently scored ≥ 9 (Light Attack), whereas the control sample averaged 3.5 (worse than Heavy Attack). Additionally, Accoya®️ wood exhibited an average weight loss of only 1.43%, compared to the control sample's average of 32.06%.

MACHINABILITY

Processing does not affect the unique properties of Accoya® wood, as it is modified throughout and not leachable. It is relatively easy to process and can be compared to profiling a soft wood species. No special tools are required for cross cutting, ripping, planing, routing and drilling. Sanding before finishing is rarely required.

GLUING

Both load bearing and non-load bearing applications have been tested using adhesive systems related to laminating, finger jointing and frame corner joints. While good results can be achieved with most common adhesives, PU, epoxy and PRF adhesives give the best results. The results of gluing with polyvinyl acetate (PVAc) and melamine urea formaldehyde (MUF) can vary greatly. Specific recommendations for your project are available upon request.

FINISHING

Most commonly used coating systems can be used on Accoya® wood. Testing has been performed with a full range of oilbased and water-based coating systems. Leading coating manufacturers have found that their products last three or more times longer when used on Accoya® wood. Specific recommendations for your project are available upon request.

Material

100% Solid Accoya® Wood

DURABILITY

EN 113 Class 1 (the highest rating). It is an effective barrier against a broad spectrum of fungi including cellar, wet rot, dry rot, soft rot, white, brown and pore fungi.

EQUILIBRIUM MOISTURE CONTENT

3 – 5 % at 65% relative humidity, 20°C

DENSITY AND SPREAD

65% RH, 20°C, Average 512 kg/m³, Range 432 to 592 kg/m³

SHRINKAGE

FIRE RATING

Class C (ASTM E84) and D (EN14915). Accoya® wood can be firetreated to meet higher requirements.

THERMAL CONDUCTIVITY

EN 12667, λ = 0.12 W/m∙K

BENDING STRENGTH

EN 408, 40 N/mm²

BENDING STIFFNESS

EN 408, 8800 N/mm²

JANKA HARDNESS

ASTM D143, Side 4100 N, End grain 6600 N